Offer

Oil laboratory

Our oil laboratory offer includes:

- laboratory services in the field of testing insulating oil used in power electric equipment, e.g. transformers, chokes and switches

- physicochemical tests (water content using the K. Fischer method, breakdown voltage, resistivity, surface tension, dielectric loss factor tg δ, kinematic viscosity, flash point and acid number, etc.)

- chromatographic tests of gases dissolved in oil (Dissolved Gas Analysis) on portable analysers and stationary chromatograph

- soil and liquid acidity tests

- vacuum treatment of oil to improve dielectric parameters by cleaning, drying and degassing

- sale of transformer oil

- oil spinning service

- purchase of used transformer oil along with issuing a waste transfer card

- sale of treated silica gel

Maintenance of many mechanical devices requires periodic testing of the operating oil. Every car owner knows this – but not everyone knows how important oil is in power equipment. First of all, it is about transformer oil. The parameters that the liquid must refer to the efficient, effective and safe operation of the entire power grid. Transformer coils heat up intensively during normal operation and require liquid cooling. The liquid must have a very high resistivity and resistance to electrical breakdown. It should also be inert and chemically stable. Mineral oils meet these requirements. Their examination and conservation are very responsible tasks. Alterga has an advanced oil laboratory where we recognize defects and wear symptoms of both the oil used and the transformer in which it was located. Oil diagnostics is one of our specialties!

Oil testing in the laboratory

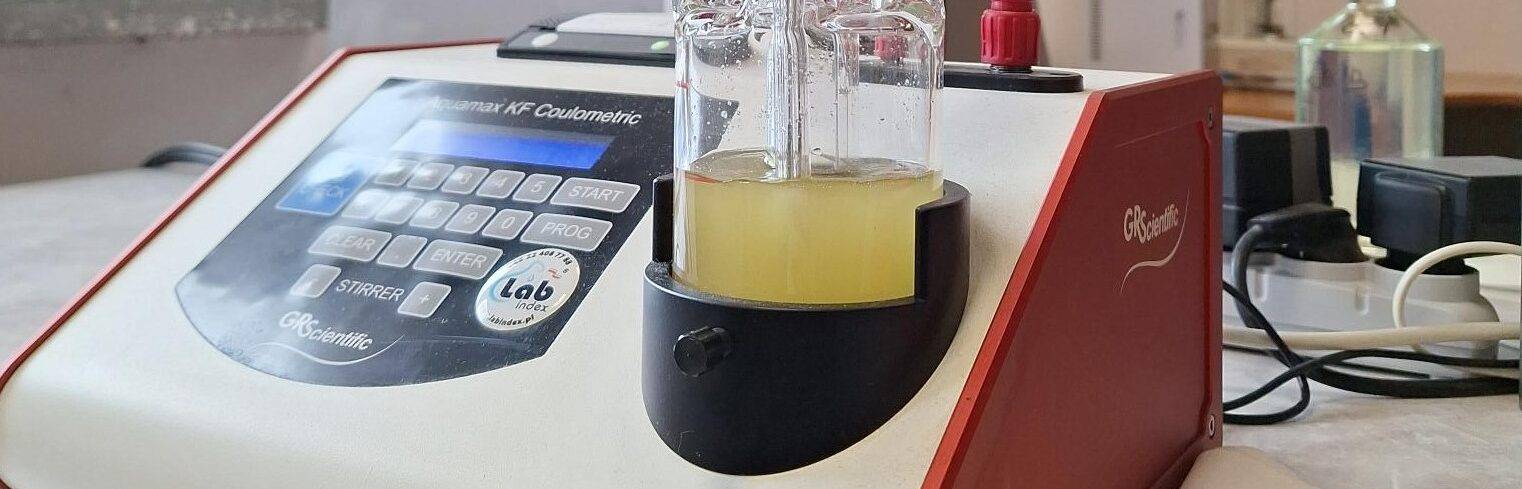

Work in the laboratory is focused on precisely measuring the physicochemical properties of oils. The appropriate oil must have good electrical insulation because it is in direct contact with live components. The standards also include flammability, water content, chemical elements such as hydrogen, acidity, density and viscosity. The Alterga laboratory performs the following tests of electrical parameters:

- breakdown voltage

- resistivity

- dielectric loss factor tg δ

Oil diagnostics also examines the following physical properties:

- surface tension

- kinematic viscosity

- flash point

- acid number

- water content (K. Fischer method)

In addition, we have equipment to determine the amount of gases dissolved in oil (DGA test – Dissolved Gas Analysis). We use a stationary chromatograph and portable analysers for this purpose.

Most of the above parameters indicate various aspects of aging of oil or electrical equipment. Over time, transformer oil may become contaminated. This cannot be completely prevented because – at least partly – it comes from inside the transformer. Solid particles, i.e. sediment, come from the degradation of cellulose insulation or corrosion. They deteriorate the cooling properties of the oil, increase dielectric losses and reduce surface tension. Moisture increases the risk of corrosion and reduces resistivity and breakdown voltage. The slow decomposition of the oil acidifies it (the acid number increases) and reduces the flash point.

Oil processing

Large power transformers contain large amounts of oil, often over a dozen tons. For practical and ecological reasons, replacing the entire amount is often not profitable. Disposal costs are not small, in addition to the purchase of fresh oil. Cleaning the oil instead of replacing it leads to the production of several dozen times less harmful waste. In our laboratory, we can regenerate transformer oil. Its wear parameters often allow it to be safely used for many years after appropriate treatment. It is primarily an oil centrifuge. This leads to the separation of solid particles, i.e. removal of sludge. Moisture and undesirable gaseous admixtures are also removed. Oil centrifugation is carried out under significantly reduced pressure (vacuum treatment) to accelerate the separation of contaminants. It significantly improves dielectric parameters (resistivity, loss factor, breakdown voltage). It also reduces the water content and acidification of the oil.

Purchase and sale of oils

If the installation has been significantly neglected, there is only one thing left to do – replace all the oil. Then a problem arises in the form of hundreds of kilograms of harmful waste. If left alone, it poses a risk of leaking into the soil and polluting the environment. Fortunately, the Alterga laboratory also purchases used oils. We issue a waste transfer card, so from a formal point of view the process is approved and legal. In addition, we sell new transformer oils and silica gel. It is an active substance used in transformer dehumidifiers. Thanks to them, moisture – a real threat to the operation of the transformer – is significantly reduced.

At Alterga we have experienced professionals. We carry out all necessary tests and effective treatment of transformer oil. Find out more – contact us!